tel:13817120160 tel:13817120160

email:mxx@jeeao.com email:mxx@jeeao.com

|

Details

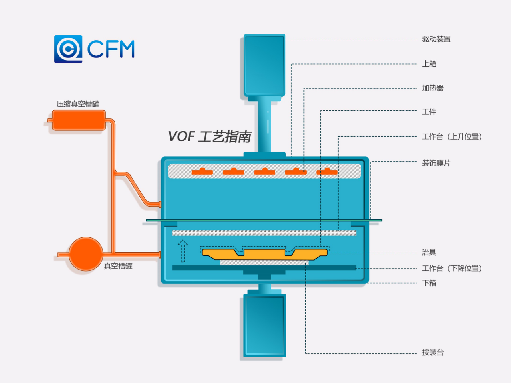

| TOM is a 3D surface decoration process that can achieve higher-quality appearance effects, and belongs to the three-dimensional appearance decoration technology. In layman's terms, it is the third generation of OMD (Out-of-Membrane Decoration Process), which combines color, texture and other texture effects in one, and can be used for complex curved surface decoration. At present, air pressure is mainly used to cover the appearance of the product. Through the different effects of the diaphragm, it can be decorated into various surface effects imitating other materials, such as wood grain, stone Texture, leather, carbon fiber, paper cloth, etc. Generally, the benchmarking processes include printing technologies such as water transfer heat transfer printing, gold plating, spraying, IMD and other decoration technologies. |

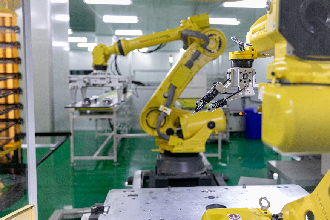

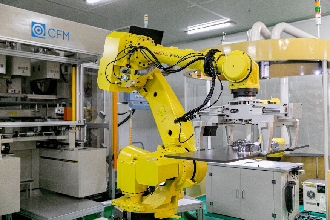

cut arm |  Robot arm |

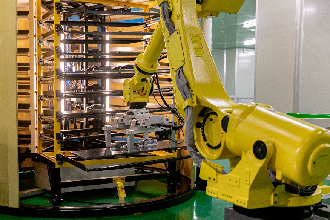

Jig Library |  Carousel |

It can be applied to various substrate materials, not limited to plastic, glass, metal, wood, etc. |

|